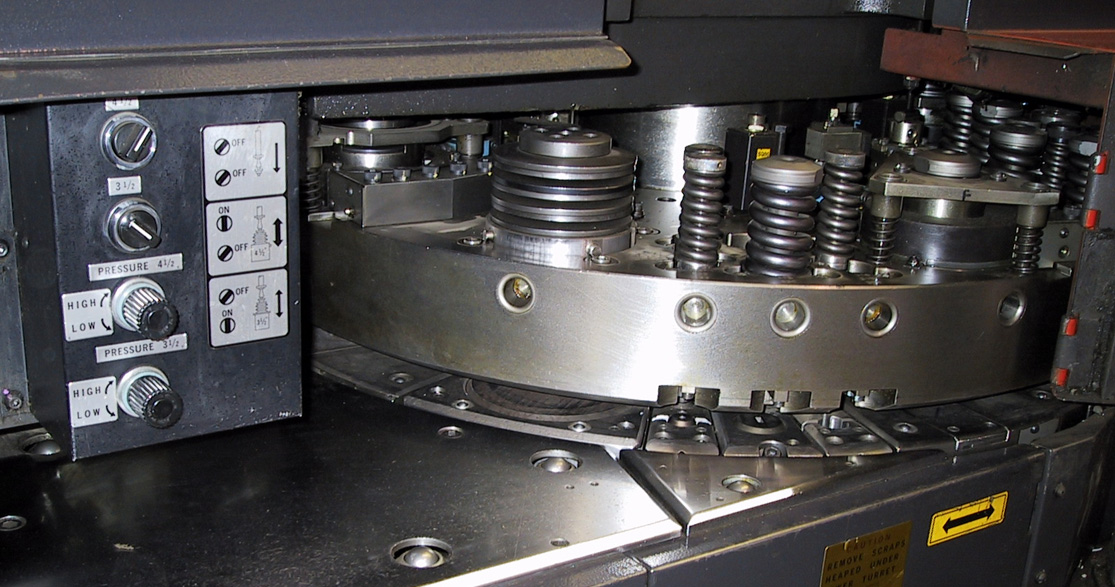

Punching machines come in many different styles and configurations. A simple punch machine offers a table to hold and gauge the material with a hydraulic, mechanical, or servo-electric motor driven ram that pierces through material with a punch and die combination. This machine requires you to change the punch and die combination for each and every shape and size of hole you require. These simple machines can be either CNC or manually operated. A turret punch machine operates on the same principle however it contains many punch and die combinations that are readily available. These punches and dies are setup in a turret disc that rotates into the ram punch position when called for in the machine (G) code program. Since these machines require extensive programming they are all CNC operated. As a CNC operated machine they are programmed beforehand and are commonly used for repeated products that require high precision.

Our CNC turret punch press is capable of cutting through 1/4″ thick steel, stainless steel, and aluminum with an accuracy of 0.004″ over a sheet size of 50″ x 144″. The machine turret is configured for 45 stations of which 4 are auto-index rotating. In addition to the 45 punches and dies that are always setup in the machine we also have a huge inventory covering nearly every shape and size available. With our cutting edge CAD and CAM software package we can quickly and easily make any parts you require.