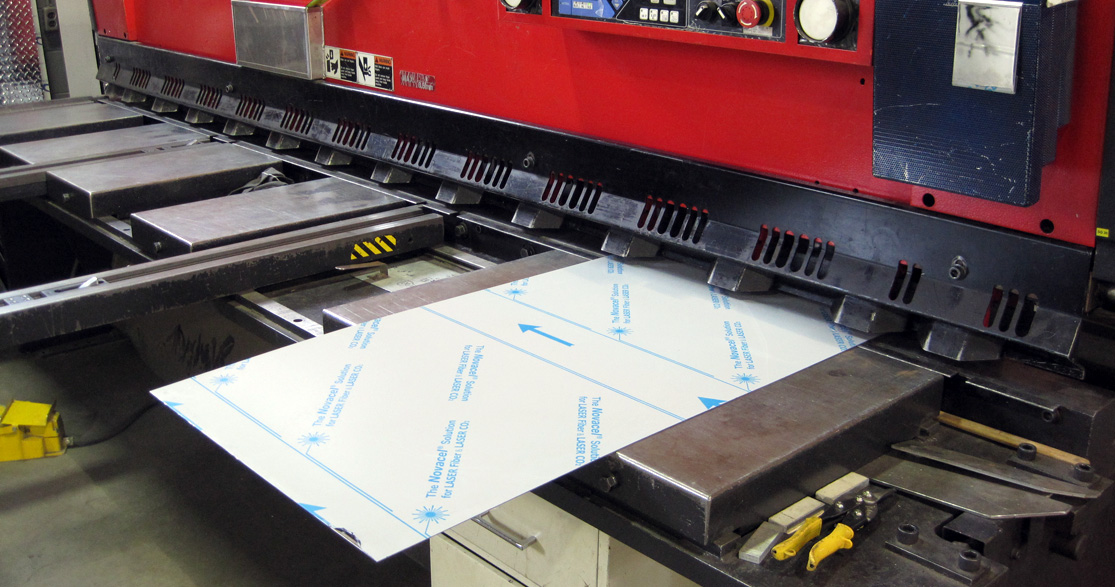

A shear is perhaps the most common machine you will find at any metal fabricator. This is simply the more efficient machine to make straight cuts in sheet metal. The machine operates two sharp blades similar to aviation snips or scissors. The blades are arranged in a horizontal position and the bottom blade is fixed. The top blade is actuated with hydraulic or mechanical forces and meets the bottom blade in order to cut the material. Shears normally come with a backgauge that allows you to control the amount of material to be cut. Most shears available today are CNC controlled but there are still plenty of older shears that require manual operation of the backgauge, clearance, and rake angle settings.

Our CNC shears are capable of cutting through 1/4″ thick steel, stainless steel, and aluminum with sizes exceeding 120″ in length with incredible accuracy.